The Supervisor serves as an Information Center, managing the operation of all equipment. With high performance, allows a wide range of connections: connecting to a LAN, or Internet connection, distributing information and ensuring connection to each equipment. With this exclusive feature, new systems and appliances can be interconnected without need to purchase other equipment parts, ensuring increase functionality without exchanging control panels that in other systems is extremely expensive.

The Supervisor is the main part of the S2 system, and provide connection with the seals, probes and sensors located in hazardous areas. Customers can receive real-time notifications of critical alarms access site history and analytics and compliance information; obtain inventory and delivery information, and many others. It manages supply and all algorithms to provide full information to each user. In a same site, many users could access information at the same time. It has internal intrinsic safety barriers, in compliance with international safety standards.

The Supervisor has the following features:

- Eight slots with Triple Barriers that support up to 24 different devices (SmartProbe, or SmartSeal, or MuxLiq), all in a single enclosure;

- Ability to monitor up to 192 interstitial areas and/or containment areas utilizing a standard float style sensor.

- Full-Range Power supply, operates on any AC voltage between 90 and 250V.

- Base platform with additional features, these features allow more control of the system as a whole.

The Ethernet interface support connections of POS and local area network simultaneously. Provide two USB interface and one RS232 for external connections. It can be connected to Dispenser Control Modules for selling conciliation.

Performs static tank tightness test with an accuracy of 0.1 GPH with at least a 95% probability of detection, totally programmable. User can define the start that test can run and the period to be running.

The system shall have the ability to provide a record of each type of alarm or warning condition detected by the system and maintain up to one year.

With many alarm configurations, users have access to several alarms as:

- Maximum product level

- High level limit

- Overfill alarm

- High water alarm

- Low Level alarm

- Delivery needed alarm

Acts as a web-based portal that provides operators to monitor, configure, and control all of their wetstock management assets.

As a Server based platform, browsers or mobile devices can connect directly on it over a Wi-Fi or LAN, in a simple way.

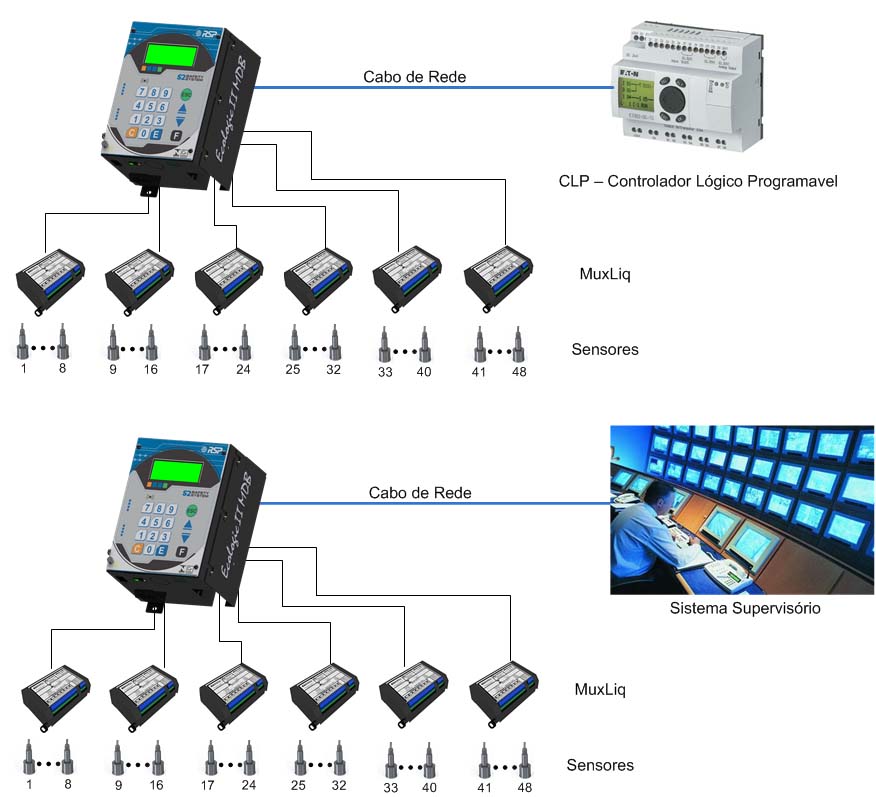

ModBus Operation

The supervisor can also operate with a ModBus interface in order to realize the environmental monitoring and tanks gauging that can be distributed in a fuel storage forecourt. Can operate both through Modbus RTU protocol (Ethernet) and IP ModBus protocol. It's dsigned for systems that already operate with BMS (Building Management Systems) or PLCs (Programmable Logic Controllers) and require environmental sensors monitoring or tanks gauging in hazardous areas.

Safety System Operation

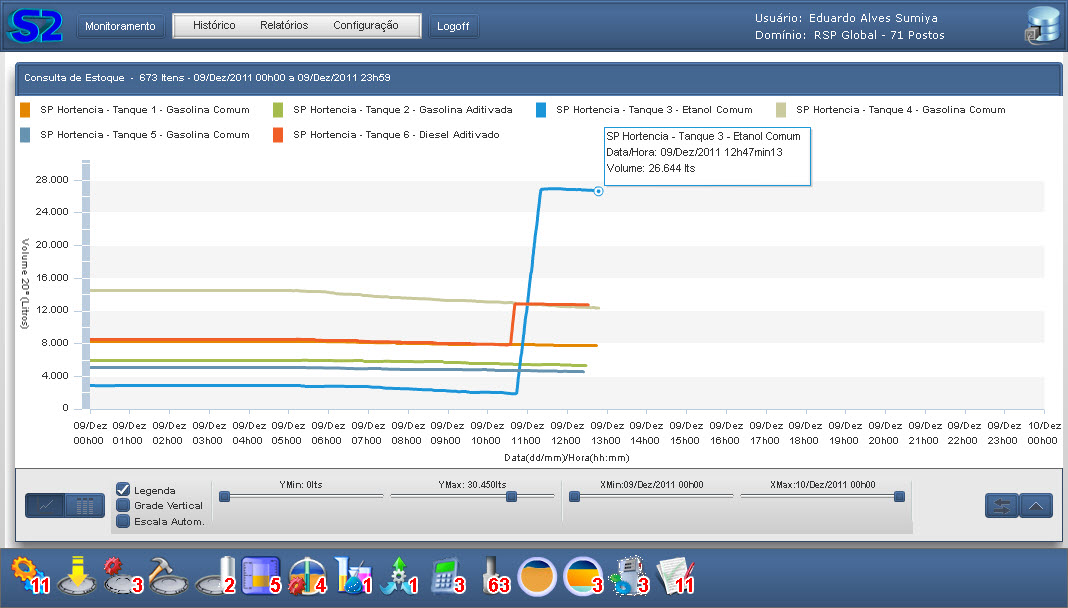

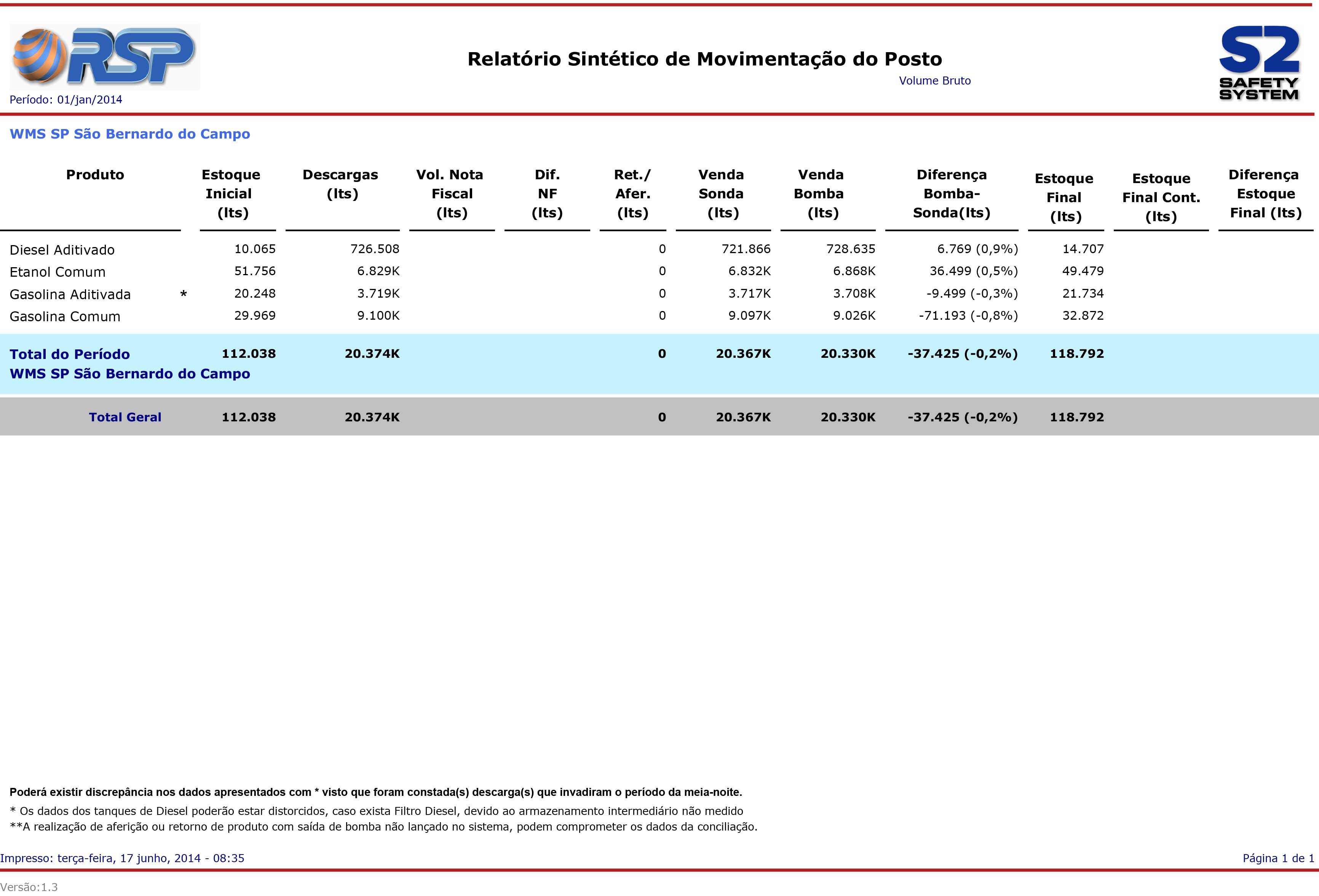

With Premium software, you can manage efficiently access critical data and reports from an unlimited number of ATGs. Information is collected to provide on-demand access to alert messages, inventory and delivery data. Provides email and SMS compliance update status to pre-defined users. Customized alarms with user profile to ensure appropriate site action.

With S2 Updater and Premium Software allows easy local or remote upgrades for future requirements.

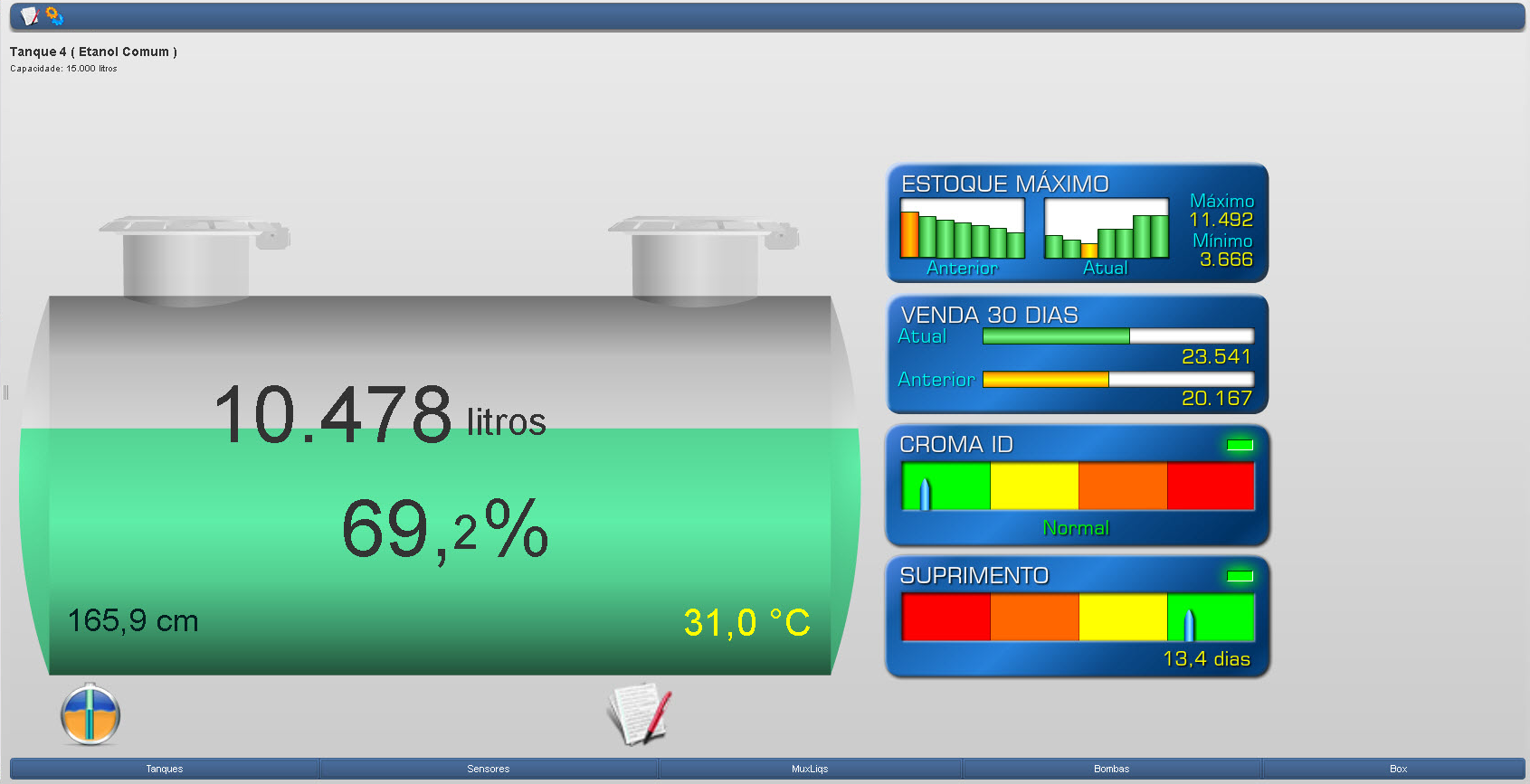

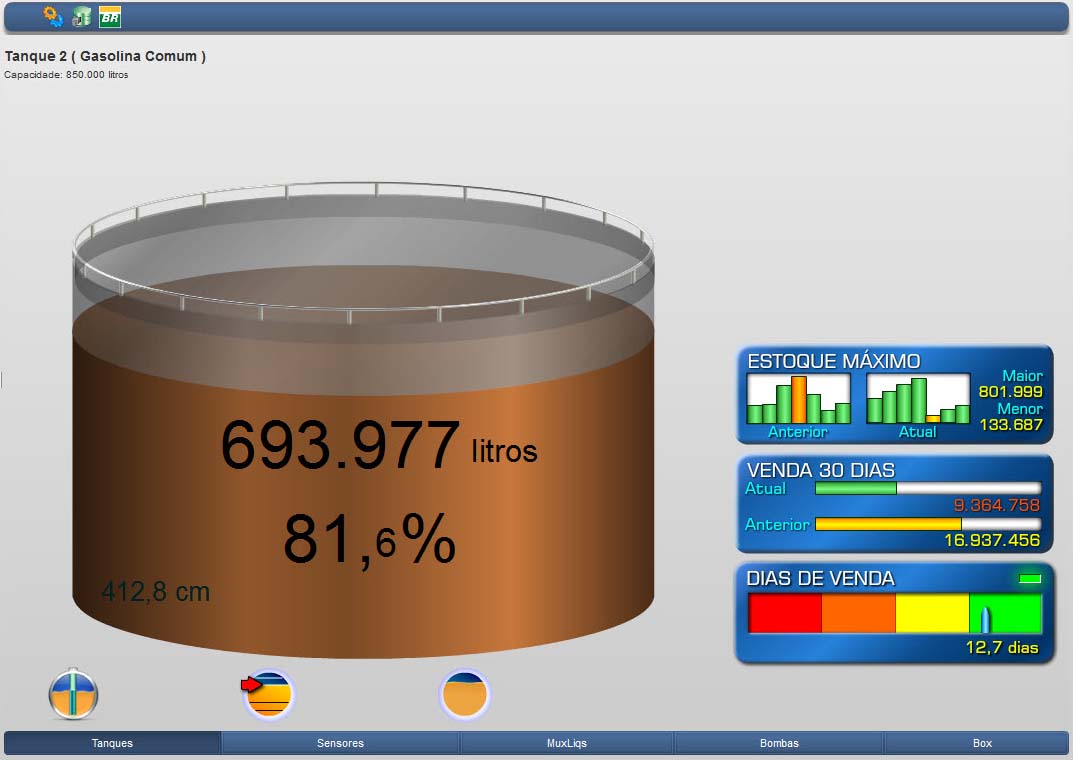

The dashboard gives a Tip to all information. Training and Learning is now simple. With a user- friendly dashboard with a real time motion all information is at your fingertips. You can even diagnose the health of main pieces of your system.

Supervisor has internal algorithm to send data in real time to Cloud. Different of other systems, that are updated only two or three times a day, S2 Systems provides real time information, because user have to make decisions upon very accurate data. Reports are generated in a PDF format in color giving a high level of information, in an easy way to understand the relationship between information, and could be sent by e-mail or printed in any local printer.

A great variety of reports, that can be selected and filtered provide a wide range of conciliated information. With connection with dispenser controllers you have a Business Inventory Reconciliation, where fuel delivery could be made while a customer was pumping gasoline, without interference in reports. An internal relay with dry contact could be use to enable external audible or visual alarms. You can select at any time the language supported.

Technical Specifications

|

Dimensions

|

Internally to SmartBox

|

|

Weight

|

10 kg

|

|

Operation Temperature

|

0 to 40 °C (32 to 104 °F)

|

|

Humidity

|

90% (Max) Not Condensing

|

|

Installation Place

|

Internal Security Area

|

|

Power Requirements

|

110V or 220V AC

|

|

Local Network

|

10/100 MBits/s (for ADSL version)

|

|

External Modem

|

V90 pattern or superior (for Dial-Up version)

|

|

Communication

|

RS 232 / RS 485 / USB / Ethernet

|

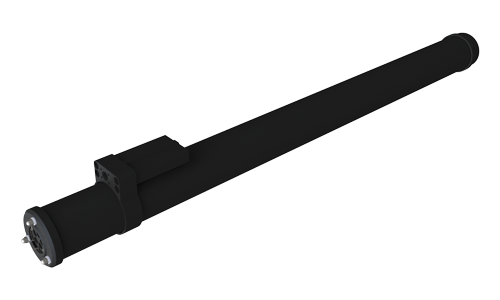

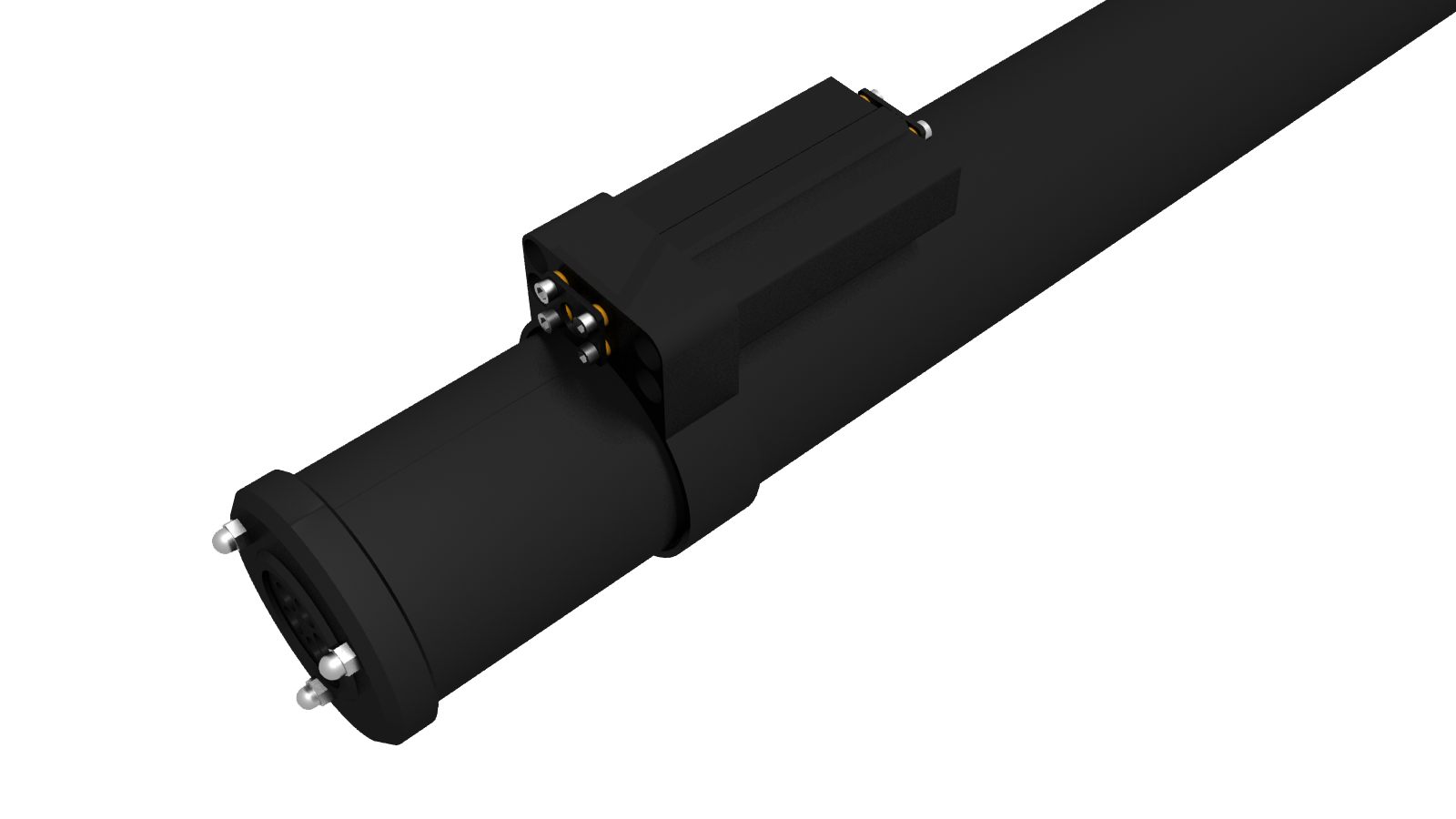

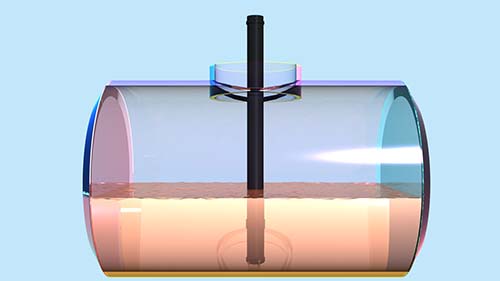

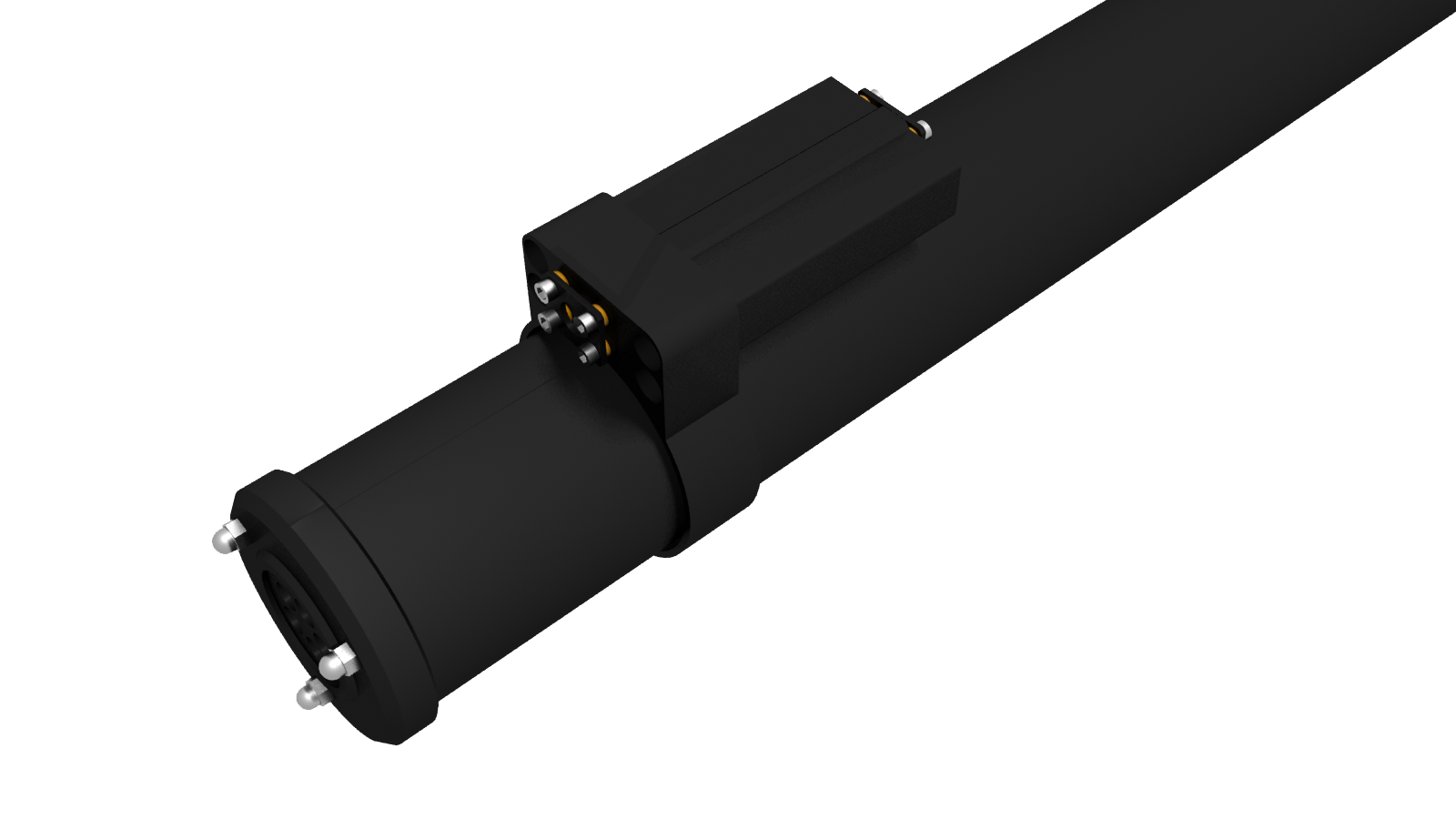

Smart Probe is a smart device designed for accurate tank gauging. With a robust construction has sealed floaters for better security and has the capability to identify markers (CromaID add on) accurate tightness tests (0.1 gal/hour or 0.2 gal/hour), volume compensation (net volume) and many others features. With continuous monitoring , using S2 Platform could inform sales forecasts, and tank compensation.

With a resolution of 0.01 mm (0.0004 inches) and could identify minimal product oscillations inside tank.

Automatic Tank Gauges with RSP Technology are a new concept of operation and data quality: Accuracy and Safety. No other can offer some of these functionalities and capability. Smart Probe design offer auto calibration achieved by special digital circuits an algorithms that could provide automatic calibration continuously. The devices don’t need any kind of calibration avoiding undesirable measures deviations that could occur in conventional probes. Using until 8 temperature sensors distributed along the probe, data could be read with a 0,0625 0C (0.1125 oF) resolution to achieve better temperature conversion.

Smart Probe has an optical technology could do accurate tank gauges, tightness tests and water measurement. Are build in regular sizes of 1,95 mts (77 inches) and 2,54 mts (100 inches), but can be built in special sizes.

The reading principle is based in an optical beam tracing the product level. The optical technology provides accurate readings even in high unstable levels, which represents much more accurate deliveries. Tracing is made by a special secure processor.

Another feature is the capability of reading two liquid sensors locally. With this, monitoring well and tank sump sensors could be solved locally. CromaID is an exclusive feature to control the behavior of the product quality.

Reading the amount of light absorption of each light wavelength and a dedicated software algorithm, it could inform each standard of the delivered product in the tank.

SmartProbe is installed in the manhole of the tank. If you use a pump controller, the S2 System platform could integrate all data, providing the capability of selling during deliveries, because each refueling could be read in real time and considered to determine the amount volume delivered.

Specially designed, floaters are protected inside the probe. This prevent float to be locked by product elements that could contaminate tank and for safety purposes. Optionally, probes could be offer with challenge type protocol for secure data locations.

Operation on Safety System

Screens are presented to the user with a lot of details. Level, temperature, and operational data are shown in an intuitive way. When using CromaID, a dedicated dashboard show the product quality.

Another screens presents the real behavior of the tank, showing historical data. Adding, several tools (like zoom and scale factor) could be used to auditing and retrieve important data.

Technical Specifications

|

Dimensions: 1910 mm version

|

70 mm (Diameter) x 2255 mm (Height)

|

|

Weight

|

5,9 kg

|

|

Dimensions: 2549 mm version

|

70 mm (Diameter) x 2320 mm (Height)

|

|

Weight

|

7,0 kg

|

|

Operation Temperature

|

0 to 50 °C (32 to 122 °F)

|

|

Humidity

|

Immersed on Tank

|

|

Place of Installation

|

Tank Sump

|

|

Power Requirements

|

12 VDC 100 mA by Security Barrier

|

|

Approvals / Certificates

|

CEPEL

|

|

Communication

|

RS 485

|

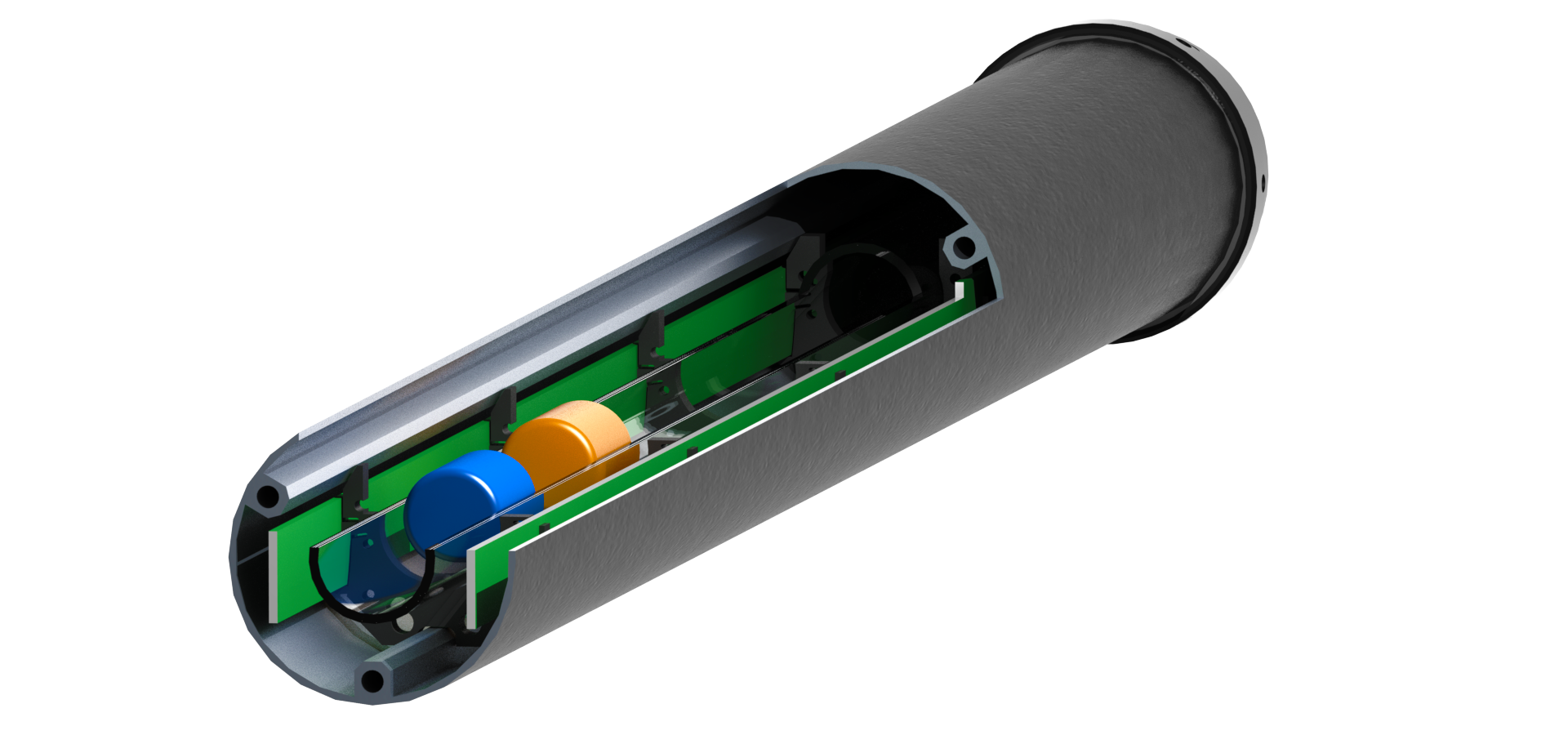

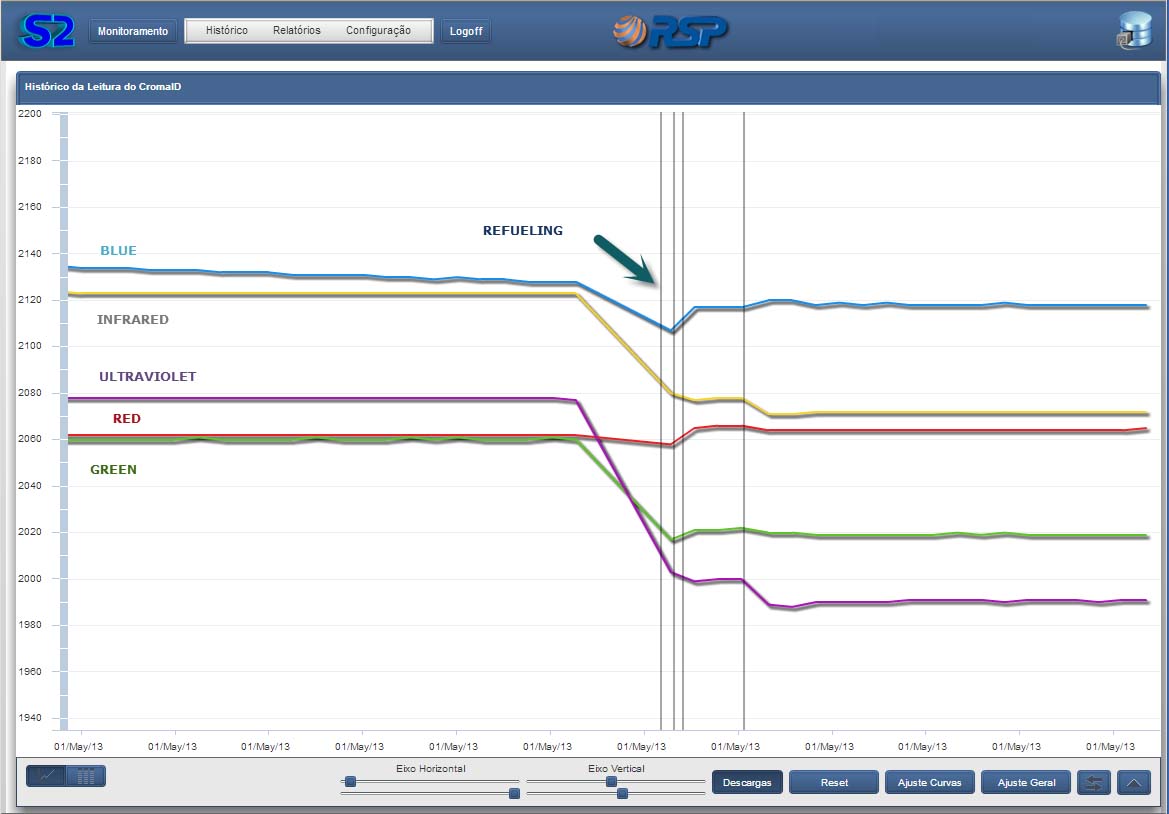

The CROMAID device was specifically designed to monitor in real time the behavior of fuel pattern. SmartProbe is an accessory located near at the bottom of the tank.

CromaID is an electronic device that directs light beams (in visible and non visible spectrum) through the fuel, performing an statistical analysis of the result of light absorption. For each type of fuel (like ethanol, gasoline or diesel) each light beam is absorbed differently, because each product has a distinct absorption identity.

Directs light beams (in visible and non visible spectrum) through the fuel, performing an statistical analysis of the result of light absorption. For each type of fuel (like ethanol, gasoline or diesel) each light beam is absorbed differently, because each product has a distinct absorption identity. This colorimetric assessment type, but without relationship with a chemical analysis, allows small changes to be observed in standard product.

Operation

To do an accurate analysis, the CromaID evaluate automatically the first’s deliveries in “learning” mode. With this “learning” it can define the correct parameters of how to evaluate the product inside the tank. The parameters has direct relation to the product variation and are considered to determine the exact behavior of each product.

|

|

When using markers the efficiency of the detection could be better due a standardization and low variance in regular refueling, but even without markers, normally each company has its own standard, that contribute to better discrimination.

Tolerances are classified with their intensities and are shown in the dashboard screens.

Dashboards inform the intensity of pattern change. Patterns that exceed the normal range is defined as a "LIGHT", "MODERATE" or "SEVERE".

|

|

|

|

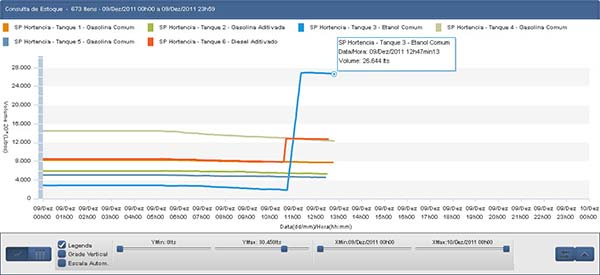

In the figure below, we can see the behavior of each CromaID beams. The vertical lines indicates a delivery occurrence. Specifically in this tank were four deliveries. This behavior occurred in a gasoline tank that before delivery we have a mixture of 20% Ethanol. After that delivery there were legal change of mixing Ethanol, moving to a new rate of 25%.

Observe the reaction of each light beam with the increase of 5% Ethanol in Gasoline. Each light beam began to operate on another level with different impacts, identifying a significant change in product. The CromaID analyzes the variation of the five beams to inform this change and the change intensity in the dashboard.

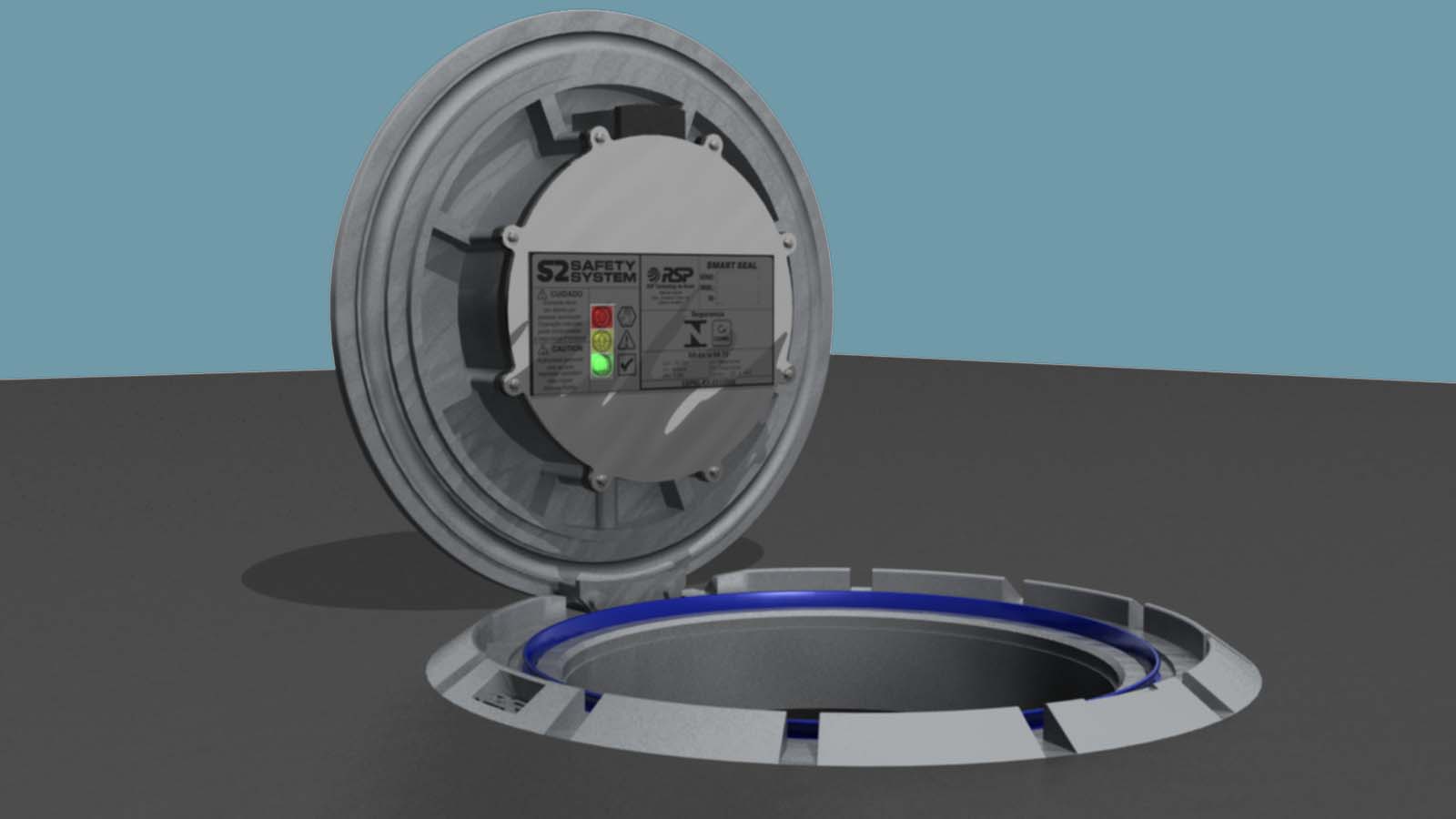

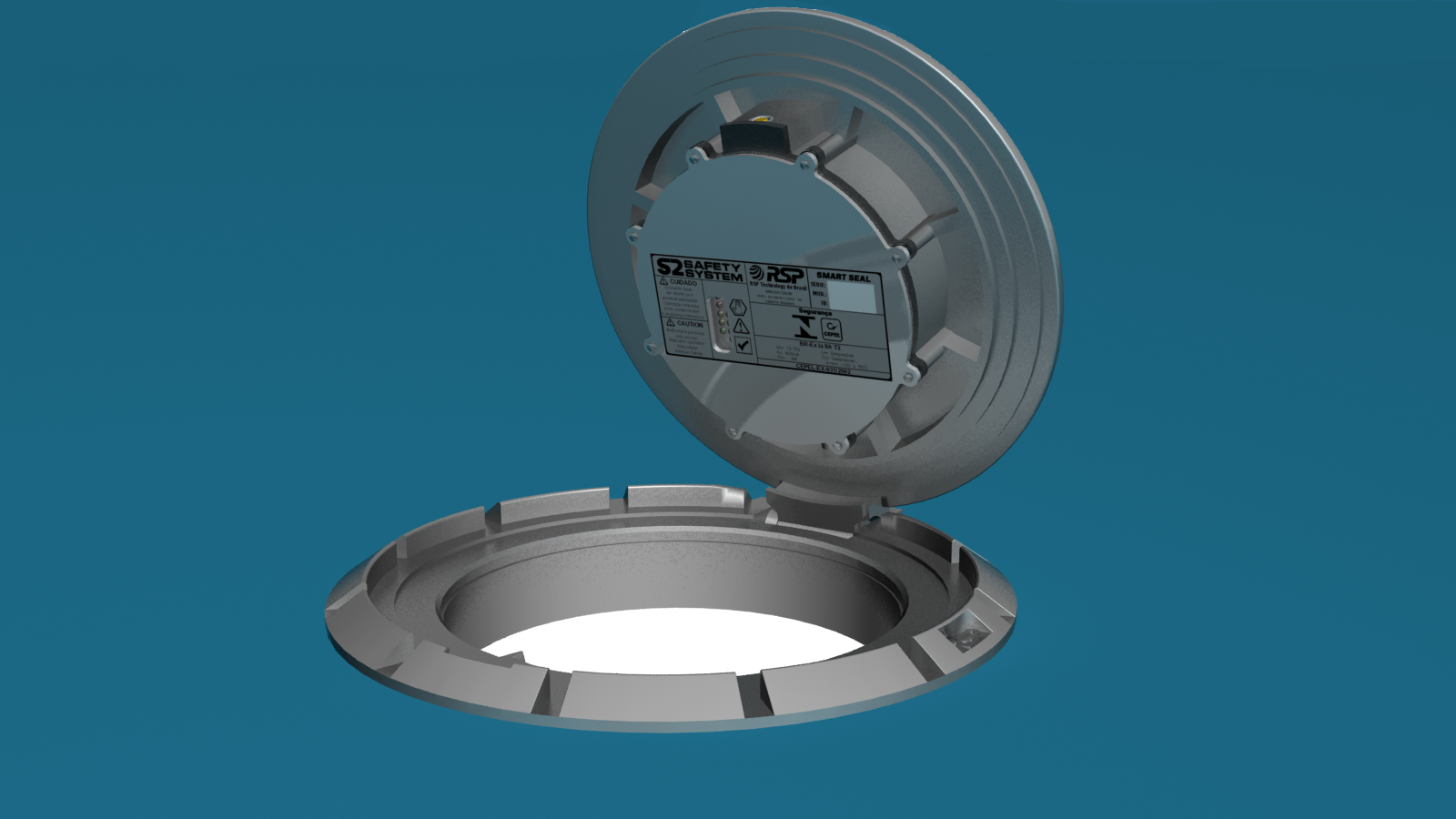

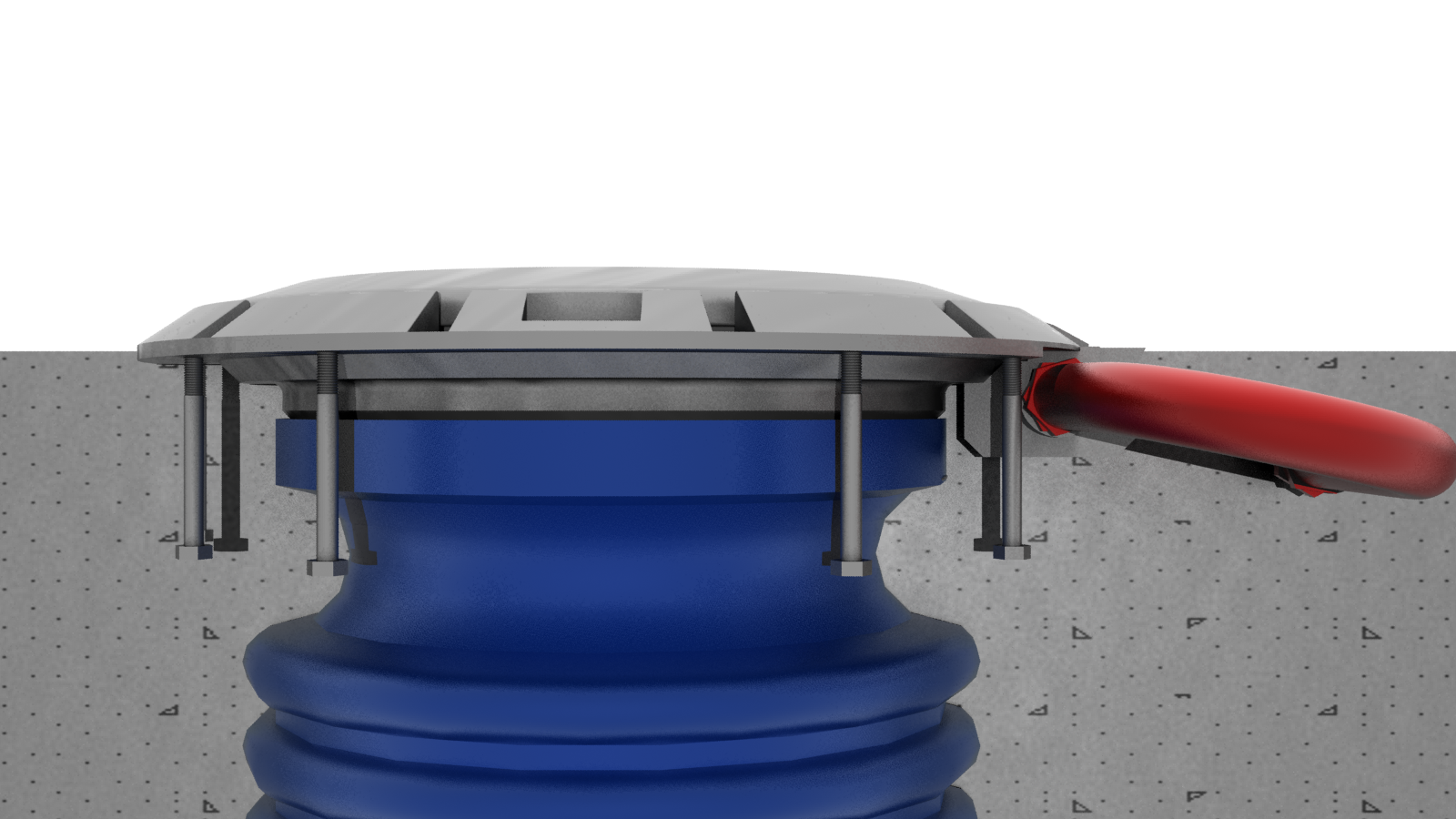

The SmartSeal is an intelligent device for fuel tanks access control, performing functions of an Electronic Seal.

Operates with Supervisor or Smart Console, performing the following functions:

- Unlocking;

- Locking;

- Storage of Operation Events locally;

- Internal control of power and batteries;

- Monitor the position sensors, locking, violation, battery, power supply, etc.

These features go beyond operating requirements of a conventional electronic seal.

The covers are specifically designed to provide a definitive control to tank access, preventing unauthorized use and maintain the integrity of all your tanks. In addition has complete integration with measuring tanks, maintaining an exchange of information with the probes in real time to provide the operator (driver) at the moment of opening the cover the current state of filling the tank to verify the possibility of overflow.

This indication to the operator prevents the occurrence of environmental liabilities that can be extremely costly.

Perform all process of locking and unlocking by local command (or remote via Internet).

Also indicates any anomalies through the Supervisor or Console locally and can send e-mail or SMS to inform warning conditions.

For full tracking and auditing all transactions are recorded on the cover in memory of secure, encrypted form. This information may be accessed at any time by the Supervisor (or Console) or even by the Monitoring System.

Each cover has an engine, responsible for the actions of locking and unlocking. Internal sensors monitor the real-time operation and the operating state of the Cover: Open, Closed or Misaligned. These states are evaluated by an internal accelerometer with high precision. Thus, the User can establish a complete tracking of all transactions on the cover. Additionally, each cover has a unique electronic ID, facilitating its maintenance. All management of the actuator position is monitored by sensors that define the exact actuator position.

Another important feature is the violation sensors. Upon determination of an external violation, the cover internally records the attempted violation and reports to other systems this event.

The cover is easily installed in the access of direct and remote delivery because it has the same dimensions of a conventional ground cover. Each cover also locally supports two sensors, facilitating the cabling of the Station, being not necessary to route the cables to the office. This represents great savings in infrastructure.

Safety System Operation

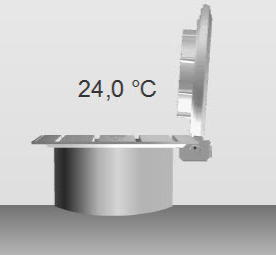

The SmartSeal is displayed on S2 System screen and allows the operator to perform all operations Locking and Unlocking, Activation and Deactivation of the cover, the Opening and Closing Seal Battery and Clearing Alarms.

By the same way the screens shows when the cover is locked, showing a padlock beside the cover image.

The screens also show the actual state of the covers (for example, when they are open):

Technical Specifications

|

Dimensions

|

Ø 400 mm x 75 mm

|

|

Weight

|

8 kg

|

|

Operation temperature

|

0 to 50 °C (32 to 122 °F)

|

|

Humidity

|

Supports Weather Changes

|

|

Place of Installation

|

Classified Area (Zone 1)

|

|

Power Requirements

|

12 VDC 100 mA via Security Barrier

|

|

Distance of the Course Engine

|

15 mm

|

|

Approvals / Certificates

|

CEPEL

|

|

Communication

|

RS 485

|

SmartConsole acts as a remote terminal of S2 System, having a keyboard and a liquid display to operate.

It was designed to be installed at the office or at the forecourt, and performing:

- Acknowledgement of alarms for leaking detection

- Locking and Unlocking Seals

- Tank Gauging

- Events analisys

Having local intelligence it was designed to replace the supervisor (ATG) in special situations. This functionality is important because it can provide a operational back up of the forecourt controller. With simple menu driven actions, user could command each tap, and verify tank gauging, deliveries, and many others. Users have to be logged in to do this operations.

The liquid crystal display have 20 columns and four lines and a keyboard with sixteen keys mounted in a metallic cabinet with tactile and audible feedback. It connects at the same net of installed taps and probes and controlled by Supervisor. The system supports until two Smart Consoles (primary and secondary) that can be installed in different points of the forecourt.

See the following diagram that shows the connection of the Smart Consoles to the Supervisor.

In regular mode, the SmartConsole is driven totally by the Supervisor. All menus and functions are controlled by the Supervisor. When using several consoles the Supervisor determines the Master Console that will operate together.

In case of fail of one of Console, the second could achieve the same kind of functionality. New features and new menus could be added to the SmartConsole to achieve more functionality.

Technical Specifications

|

Dimensions

|

200 mm (W) x 200 mm (L) x 70 mm (H) |

|

Weight

|

1 kg

|

|

Operation Temperature

|

0 to 50 °C (32 to 122 °F)

|

|

Humidity

|

Box with IP65 certification protection |

|

Place of Installation

|

Close to Fuel Delivery points |

|

Power requirements

|

12 VDC@ 100 mA

|

|

Communication

|

RS 485

|

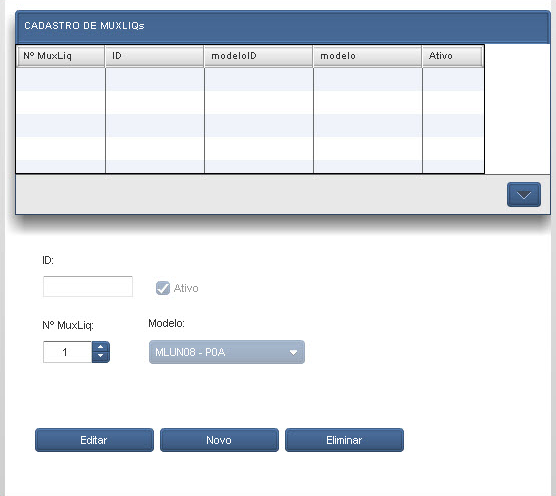

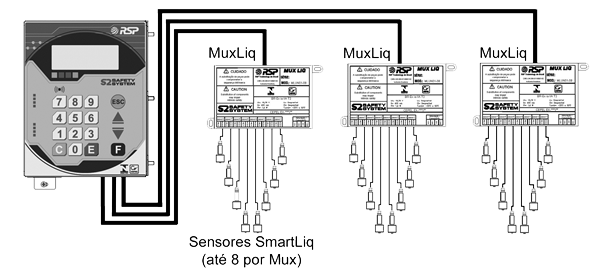

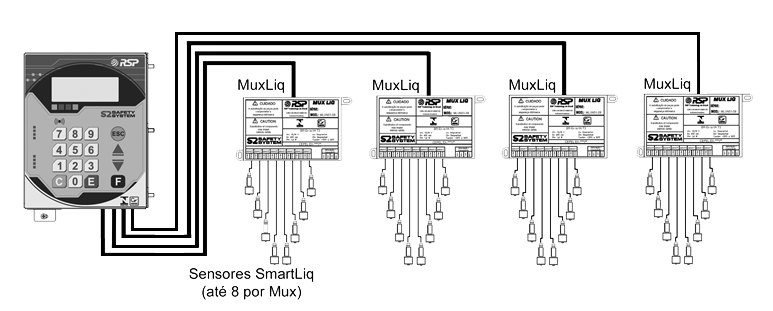

The MuxLiq is an intelligent device designed to manage up to 8 sensors SmartLiq, operating as an intelligent hub of liquid sensors. This concept allows a reduction of up to seven times the cables length used in a conventional installation.

With a compact and small size design allows to be installed inside pass boxes directly at the forecourt even in hazardous areas.

For wall installation, has side wings used to fasten and screw. A Muxliq uses only one barrier position and can support eight liquid sensors. Through local configuration user can be defined the types of sensors to be monitored: Universal or Intelligent. After connecting all cables, the equipment should be placed in a plastic bag using the RSP sealant and then must be wrapped in additional box.

Safety System Operation

The MuxLiq information can be accessed through S2 system. Once accessed, you can get the status of the device to determine if it is working.

Technical Specifications

|

Dimensions

|

Internal to Smart Box

|

|

Weight

|

10 kg

|

|

Operation Temperature

|

0 to 40 °C (32 to 104 °F)

|

|

Humidity

|

90% (Max) Not Condensing

|

|

Place of Installation

|

Internal Safety Area

|

|

Power Requirements

|

110V or 220V AC

|

|

Local Network

|

10/100 MBits/s (for ADSL version)

|

|

External Modem

|

V90 or superior (for Dial-Up version)

|

|

Communication

|

RS 232 / RS 485 / USB / Ethernet

|

Environmental sensors are device that could detect liquid presence inside double wall tanks, tank sumps and pump sumps, always with wires connected to a sealed unit. They are installed in monitoring well and they are necessary to attempt environmental requests.

In S2 platform, liquid sensor could be connected directly in one of these equipments:

- Muxliq;

- Smart Probe;

- Smart Seal

This concept of multiple connections in several devices could achieve cost benefits to the user. Less infrastructure, less cables more control.

Podem ser instalados, por exemplo, no interstício dos tanques que possuem parede dupla. Neste caso, são instalados no poço de monitoramento do tanque. Podem também ser instalados na câmara de contenção do tanque e em outros pontos da pista, como nos sumps de bomba sempre acoplados à uma unidade seladora.

There is two different kind of environmental sensors: Universal Sensor and Smart Sensor. The Universal Sensor could identify two operational states: Normal and Liquid Presence. Smart Sensor could identify four operational states: Normal Liquid Presence and two more fail condition: Short Circuit and Open. When facing a fail in installation, the universal sensor could compromise the environmental monitoring. It could inform a false situation and do not identify which fail.

Operation on Safety System

Data conditions could be easily accessed in dedicated Sensor Screen, where all sensor could be analyzed getting all meta information of each sensor : Location, Controller and Status.

Technical Specifications

|

Dimensions

|

Ø 37 mm x 97 mm

|

|

Weight

|

0,6 kg

|

|

Operation Temperature

|

0 to 50 °C (32 to 122 °F)

|

|

Place of Installation

|

Monitoring Well, Sumps and Forecourt Chambers

|

| Models |

Universal or Intelligent

|

|

Approvals / Certificates

|

CEPEL

|

|

Cable Length

|

10 meters

|

|

Installation Area

|

Classified Area

|

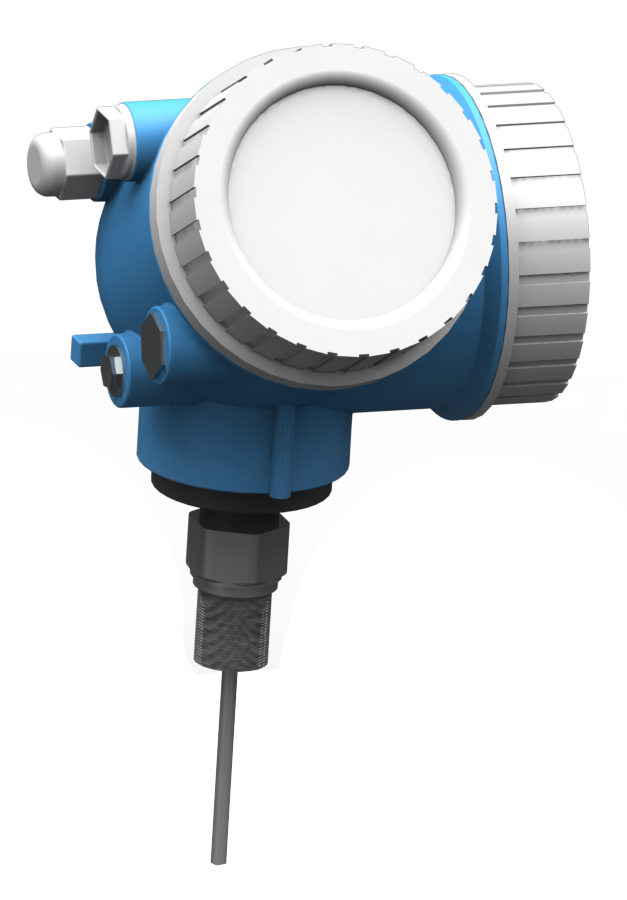

The ProbeRadar consists of a probe specially designed for huge tanks. With radar technology based on TDR method (Time Domain Reflectometry) that determines the product level by sending pulses of high frequency and analyzing its reflection on the surface of the product. Use the Dielectric Constant of the product to determine the level.

It is designed for tanks that have above 3.5 meters of diameter or high, and has two versions: One for tanks up to 12 meters and the other for tanks up to 45 meters.

Refer to the appropriate model consulting RSP technical personnel. To install the Probe Radar tanks must have a ¾ inch threaded flange. The data are performed by S2 in real-time. The volume is calculated using mathematical algorithms based on tank geometry, previously inserted. With a single power supply, it is allowed up to 4 probes connection in a same link. Can be installed in the same Supervisor (same cabinet) sharing with other optical probes.

Safety System Operation

Detailed screen presents information in a friendly way. Several information as level, maximum stock and status can be viewed easily and intuitively.

All screens show the tank profile behavior continuously. Analysis tools (such as zoom and scale change) are operator available to perform a full audit at any time.

Reports

The report system allow visualization of several variables as volumes, adjusting automatically the measurement unit, in order to present for better analysis.

Movimentation Report

Sell Report by Probe

Technical Specifications

|

Weight

|

10 kg

|

|

Place of Installation

|

Tank Top

|

|

Power Requirements

|

90 VAC - 253 VAC

|

|

Communication

|

HART Protocol (4 - 20 mA passive)

|

|

Approvals / Certificates

|

ATEX, IEC, Ex, FM, CSA

|

The Ecologic was specially designed to monitor the diverse liquid sensors distributed in a floor Gas Station. The sensors can be installed in monitoring wells in the double wall tanks in pump sump, tank sump, diesel filters and in the various chambers of sidewalk at the Station.

With Ecologic Console you can perform the following operations:

- Verification of leak alarms;

- Recognition of alarms;

- Visual and audible indication of alarm;

- Distinction to sound new alarms and recognized alarms;

- Indication of operation of MuxLiq modules;

- Change clock in real time;

- Display of generated events grouped by zone;

- Indication of date and time in alarms generation;

- "Debounce" inputs to avoid false alarms;

- Configuration of the number of MuxLiq by console;

- Connection of a siren through a dry contact indicating alarm;

- Events registrated with time stamp with second resolution;

- Allows the connection of a RS 232 printer with 40 columns for automatic print of event sequence.

The operation menus are easy and self-guiding, eliminating the use of shortcut guides or consult through special keys. The guidance menu allows quick access to all the features offered by any user, even if you have no training to operate. As has three safety barriers, can add up to 3 MuxLiqs therefore can monitor up to 24 sensors (Universal or Intelligent).

Events

All of alarms situations (leaks detected by the sensors, abnormal situations, etc.) are registered with time stamp at the moment that occurred and are called Events.

These registers let you track the history of events, verifying the sequence of how the alarms occurred, allowing a full analysis and careful of the occurrence of environmental damage and to take the correct solutions of control and containment.

The system allows the register of this history in a continuous list, in other words, the oldest event is replaced by the most recent event, but always keeping a history of 400 events by controlled zone.

For situations where you need only the Environmental Monitoring, the Ecologic Console is the ideal alternative. It’s dedicated exclusively to control specific liquid sensors, but can easily be expanded to a full system S2, with simple addition of modules, reducing significantly migration costs.

- Economical option for leak monitoring. – Operates in an independent way for exclusively monitor liquid sensors;

- Developed with the same platform as the S2, keep its investment in the upgrade of the system so that it can evolve according to your needs.

The Most advanced technology in environmental monitoring by lower price.

Features

- LCD with backlight and 4 lines of information;

- Water resistant membrane keyboard;

- Function keys for quick access.

Technical Specifications

|

Dimensions

|

359 mm (W) x 434 mm (L) x 150 mm (H)

|

|

Weight

|

1,2 kg

|

|

Operation Temperature

|

0 to 50 °C (32 to 122 °F)

|

|

Humidity

|

90% (Max) Not Condensing

|

|

Place of Installation

|

Safety and Protected Area

|

|

Power Requirements

|

110V or 220V AC - 60 Hz

|

|

Approvals / Certifications

|

CEPEL

|

|

Communication

|

RS 485

|

The Ecologic MFA has been specially designed to monitor the various sensors distributed in a Service Station, reporting all events for the Central FATMA (www.monitordevazamento.com.br). The sensors can be installed in monitoring wells in double-walled tanks in sump pump, sump tank, diesel filters and the various chambers of the station driveway. It is a unique system, not belonging to the packet S2 System.

With Ecologic MFA, you can perform the following operations:

- Leak Aarm Verification leak;

- Acknowledging alarms;

- Visual and audible indication of alarm;

- Distinction to sound new alarms and alarms recognized;

- Indication of the operation of the modules MuxLiq;

- Clock change in real-time;

- View the events generated grouped by area;

- Date and time of generation of alarms;

- Setting the number of MuxLiq the console;

- Connecting via a siren indicating a dry contact alarm;

- Events logged with time stamp with a resolution of seconds;

- Allows connection of an RS232 serial printer 40 columns for automatic sequence of events;

- Performs network connection via Ethernet for sending status of the liquid sensors.

The menus are easy operation and self-orienting, eliminating the use of guides or query via shortcut keys. The menu guidance allows quick access to all features offered by any user, even with no training to operate. Since it has three safety barriers. can add up to 3 units MuxLiq therefore monitoring up to 24 sensors (or Smart Universal).

Events

All alarm situations (leak detected by the sensors, abnormal situations, etc..) Are logged with time stamp at the time they occurred and are called events. These records allow you to trace the history of events, checking the sequence of how the alarms occurred, allowing a more detailed and careful analysis of the occurrence of environmental damage, allowing the correct solutions to take control and containment. The system allows the recording of history in a continuous, that is the oldest event is replaced by the most recent event, but always keeping a history of 400 events a controlled area.

For situations where you need only the Environmental Monitoring, the Console Ecologic is an ideal alternative. It is dedicated exclusively to the specific control of leak sensors, but can be easily expanded to a full system S2, with the simple addition of modules, greatly reducing the costs of migration.

- Economical option for leak monitoring;

- Operates independently to monitor exclusive liquid sensors;

- Developed with the same platform as the S2 system, maintains its investment in upgrading the system so that it can evolve with your needs.

The most advanced technology in environmental monitoring at the lowest price.

Features

- Liquid crystal display with 4 lines of information;

- Membrane keyboard water resistant;

- Functional Keys for quick access;

- Transmission status of the sensors over Ethernet;

- Meets the requirements of the environmental agency FATMA.

Technical Specifications

|

Dimensions

|

359 mm (W) x 434 mm (L) x 150 mm (H)

|

|

Weight

|

1,2 kg

|

|

Operation Temperature

|

0 to 50 °C (32 to 122 °F)

|

|

Humidity

|

90% (Max) Not Condensing

|

|

Place of Installation

|

Safety and Security Area

|

|

Power Requirements

|

110V or 220V AC - 60 Hz

|

|

Approvals / Certificates

|

CEPEL

|

|

Communication

|

RS 485, Ethernet

|

The Ecologic MDB was specially designed to monitor the various sensors distributed in a Gas Station, reporting all events through communication via Modbus RTU. Suitable for systems BMS (Building Management Systems) that communicate via Modbus RTU (eg PLCs). Sensors can be installed in monitoring wells of double-walled tanks, in sump pump, sump tank, diesel filters and the different cameras sidewalk stand. It is a single system, not belonging to the S2 System package.

With Ecologic MDB, you can perform the following operations:

Check leak alarms;

Acknowledging alarms;

Visual and audible indication of alarm;

Distinction to sound new alarms and acknowledged alarms;

Indication of the operation of the MuxLiq;

Change in the real-time clock;

View the events generated grouped by zone;

Indicating the date and time of generation of alarms;

Setting the number of MuxLiq in console;

Connect a siren via a dry contact alarm indicating;

Events logged with time stamp with a resolution of seconds.

The menus are easy operation and self-orienting, eliminating the use of tabs shortcut or query via special keys. The menu guidance allows quick access to all the functions offered by any user even with no training to operate. Can support up to 6 Muxliq capable of monitoring up to 48 sensors (or Intelligent Universal).

Events

All situations of alarm (leak detected by the sensors, abnormal situations, etc..) Are recorded with time stamp at the moment that have occurred and are called events. These records allow you to trace the history of events, checking the sequence of how the alarms occurred, allowing a more detailed analysis and careful of occurrence of environmental damage, allowing the correct solutions take control and containment. The system allows the recording of this history in a continuous list, ie the oldest event is replaced by the most recent event, but always keeping a history of 450 events a controlled area.

For situations where you need only the Environmental Monitoring, the Ecologic Console is ideal alternative. It devotes itself exclusively to the specific control of leak sensors, but can be easily expanded to a system S2 complete with the simple addition of modules, greatly reducing the cost of migration.

- Economical option for leak monitoring;

- Operates independently to monitor exclusive leak sensors;

- Developed with the same platform as the S2 System keeps your investment in the upgrade of the system, so you can evolve according to their needs;

- The most advanced technology in environmental monitoring at the lowest price.

Features

- Liquid crystal display with 4 lines of information backlit;

- Keyboard membrane water resistant;

- Functional keys with quick access;

- Transmission status of the sensors through the Modbus RTU protocol.

Technical Specifications

|

Dimensions

|

359 mm (W) x 434 mm (L) x 150 mm (H)

|

|

Weight

|

1,2 kg

|

|

Operation Temperature

|

0 to 50 °C (32 to 122 °F)

|

|

Humidity

|

90% (Max) Not condensing

|

|

Place of Installation

|

Safety and Security Area

|

|

Power requirements

|

110V or 220V AC - 60 Hz

|

|

Approvals / Certificates

|

CEPEL

|

|

Communication

|

RS 485; Modbus RTU (Ethernet)

|

|

Firmware Updates

|

via Bootloader

|

|

Connection Mode

|

Server or Client

|

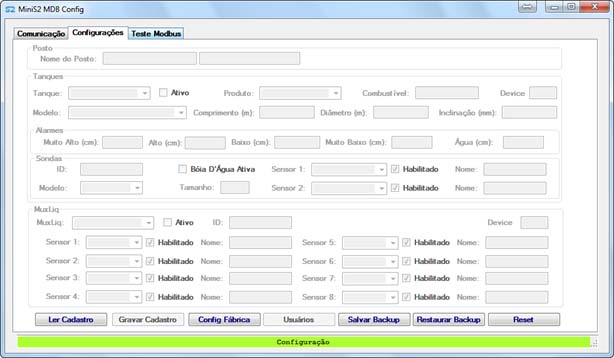

The MiniS2 equipment is a tank measuring and monitoring highly compact and robust platform based on the S2 System operating with fully distributed intelligence. Has a monitoring concept and modern graphical interface and differentiated by incorporating the main features of the S2 Management System.

For this, besides having a liquid crystal display and keypad for local viewing, the MiniS2 has a LAN interface for connecting application S2Pilot that intuitively displays all information essential for sensing measurements and the perfect management a station services.

For hazardous area has six safety barriers for connecting SmartProbe probes for accurate measurement of tanks and modules MuxLiq for environmental monitoring.

Features and Benefits

- Connection possibility up to six probes (which may bear up to environmental sensors 12) or together with up to two MuxLiqs (and most 4 probes) to reach 24 to environmental sensors;

- Continuous monitoring of volume delivery detection, alarms Level Events;

- Graphical Interface completely;Operates in stand-alone mode (without Interface S2Pilot);

- Performs the automatic timing of the information contained in MiniS2 and base data S2Pilot;

- Fully compatible with the S2 platform, allows upgrade simply by changing from the Supervisor Console.

The S2 Pilot application has a built-in database to store the information in real time and view reports and events.

Installation and setup are extremely simple using the metal bracket (included with device) and allows them to be connected cables associated equipment.

The operation of MiniS2 can be accomplished by Intuitive menus in the device itself or remotely via S2Pilot.Todo the registration information is performed graphically simplifying operation.

Make available a series of reports and graphs in real time on the real state of the tank measuring and monitoring environmental alarms.

Technical Specifications

|

Dimensions

|

Internal to SmartBox

|

|

Weight

|

2,5 kg

|

|

Operation Temperature

|

0 to 50 °C (32 to 122 °F)

|

|

Humidity

|

90% (Max) Not Condensing

|

|

Place of Installation

|

Safety Internal Area

|

|

Power Requirements

|

90/240 VAC, 50 or 60 Hz

|

|

Autonomy Time (Backup version)

|

4 Hours

|

|

External Communication

|

Ethernet

|

|

Serial Channel

|

RS 485 |

|

Place of Installation

|

Not Classified Area |

|

Display

|

LCD 4 Lines x 20 Columns |

|

SmartProbe Models

|

SP19 and SP25 (other models by request) |

|

Software

|

S2 Pilot (Windows) |