RSP Techonology is offering a new concept in global control system and remote management of fuel tanks: the S2 Safety System. S2 System is designed to manage the entire chain of fuel resupply order online and totally unassited.

Integrated Solution - The S2 Safety System consists of a set of equipment, integrated allow broad control of operations involving the supply, storage, input and output of liquid fuels resellers.

To meet these goals, the S2 System has numerous functions, technological resources, contemplating the submission of data management and administrative key to achieving operational control dedicated to the general trade in liquid fuels, enabling better, faster and more precise analysis of the wide range information, require the competitive market.

Thus, the S2 Safety System is in a much more complete and comprehensive than a simple sensing a measurement system, presenting itself as a global system of operational management and control of all the steps that comprise the suply process and suply of liquid to a dealer.

S2 System Equipments

- The SmartSeal is a device that operates as an eletronic access to the tank by controlling the effective input and output of product, preventing unauthorized access to the tank. With the same dimensions as a conventional lid, Smart Seal is easily installed on the track;

- The SmartProbe is designed to accurately measure the volume of stored product. When coupled with proprietary technology Croma ID allows the minor differences are detected in the marking of fuel;

- The Supervisor is installed in the office and constitutes the main element of S2 control, running all supervision of the devices that compose the system. One of its functions is to process the information sent to the central control and integrated data management;

- The MuxLiq operates as a hub of intelligent sensors for liquids. With its use, allows a reduction of up to seven times the distance of the cables used in a conventional installation;

- The SmartLiq is the sensor that singals the presence of liquids. Installed in the interstices of containment tanks or cameras can be connected to any of the S2 devices: Seal, Probe or MuxLiq;

- The SmartConsole is the remote Supervisor console. Installed on the track, their use enables local operation of the system without the need for access to the access.

- The Probe Radar consists in a device with radar technology. It should be used for tanks with diameter more than 4 meters (12 feet). Can be used in conjunction with SmartProbe in the same plant;

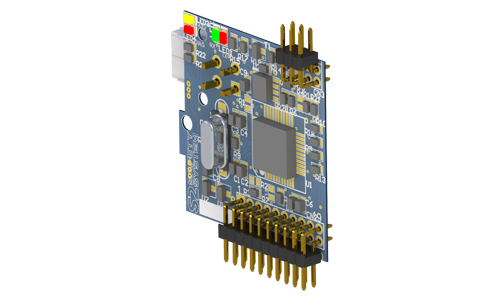

- The Ibox is a logical board designed for security and handling encryption keys. Equipped with secure and dedicated processor, it is essential for operation in environments that require safety information and tax requirements;

- The Digiout is a device capable of allowing a control drives and control supervisor. Integrated into the software, can be configured through a specific application to perform a set of operations on a fully unattended sites based on information collected in other devices such as volume, temperature, level and others;

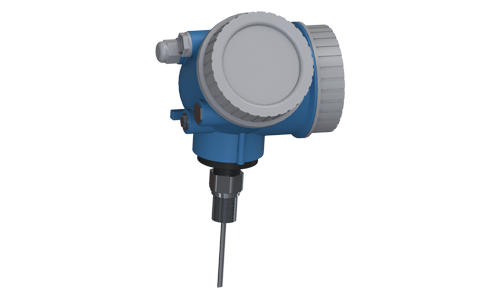

- The Smart Thermo is a temperature probe with continuous temperature monitoring and tracking. It can be used on tanks of up to 45 meters, and performs the measurement of temperature digital form with a resolution of 0.0625 °C (0,1125 °F).

S2 System Software

The S2 System basic concept is present information through any browser open within S2 Supervisor network. With Browser, you can obtain an intuitive and graphically all S2 System's operating facilities. To perform all monitoring functions, control and registration of information.

There are two modes Control System S2: the Advanced and Premium, each one having ideal tools for managing your business. The system has several features that enhance your gas station management. It is possible to obtain operating data from all integrated equipment, historical volumes, smart seal control, product level, fuel quality, discharge records, stock charts, and more. Alerts can be sent via SMS, reports or accessed in you mobile phone.

With a modular design, additional control features can be added, such as Fleet Control, Controlled Pump Calibration, and integration with industrial systems. It supports several forms of connection to exchange information, either through physical communication ports (network, serial ports or parallel ports, USB) or via TCP / IP connections, DDE. With this, all the information received from the systems connected to the S2 System will be available and managed in the same way that the information collected by current systems.

The Data Management Integrated Center combines alarms information providing data access only for authorized users, getting reconciled information from all service stations. Information can be retrieved in real time, dynamically interacting with each service station.

In a simple way, product delivery operation may be authorized with automatic registration of all steps. Also, through a simple smart phone covers can be locked or unlocked.

Put in your hand instantly valuable information as inventory volumes, sales and delivery. Emergency situations are also monitored in a real time. Leaks, unauthorized openings or equipment violations are reported immediately for effectiveness decisions.

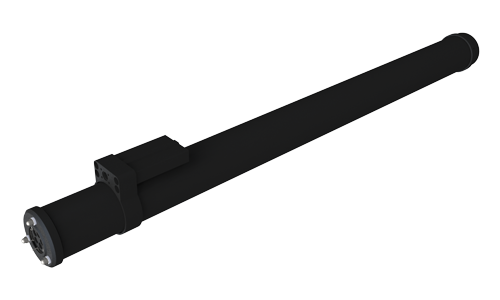

MuxLiq

MuxLiq